by | Sri Widias Tuti Asnam Rajo Intan, sriwidias@might.org.my

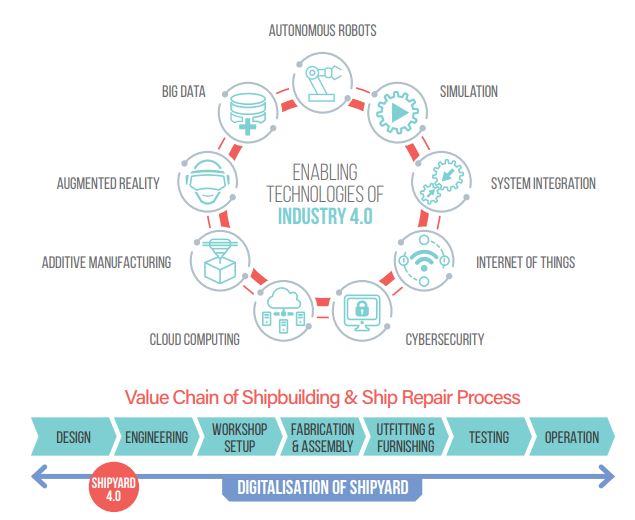

Shipping organisations face intense pressure to operate in a more efficient and profitable manner while catering to the increasingly sophisticated demands of their customers. The advent of Industry 4.0 has introduced a new way of work for the ship building and repair sector, allowing the integration of physical and virtual world to optimise production within the industry. The digitalisation of the shipyard has the potential to be a revolution for the industry.

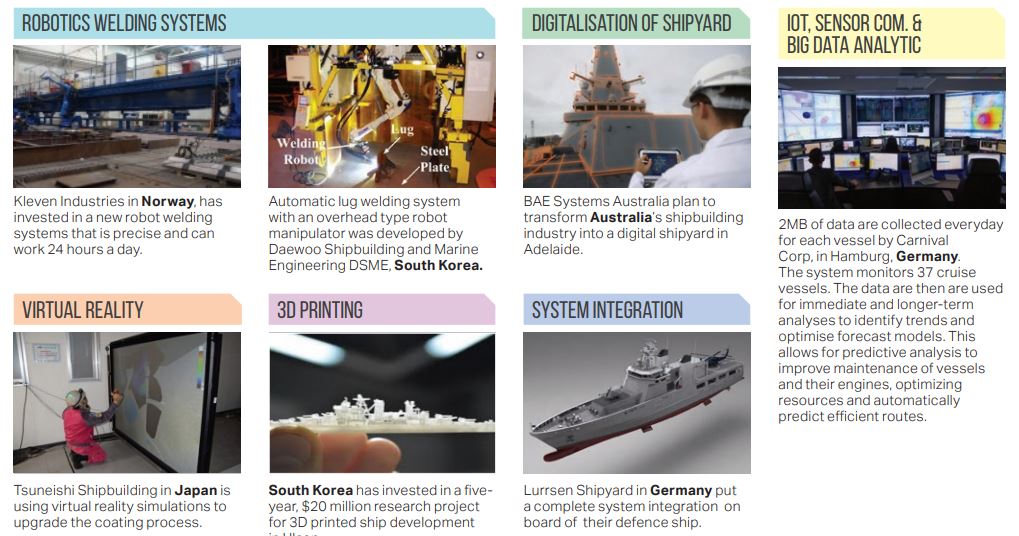

Industry 4.0 in SBSR (Examples in Leading Countries)

Advancements in IoT, Work Automation, System Integration and other I4.0 enabling technology will further elevate productivity of the workers.

Shipyard 4.0 Concept: Case Study

Australia:

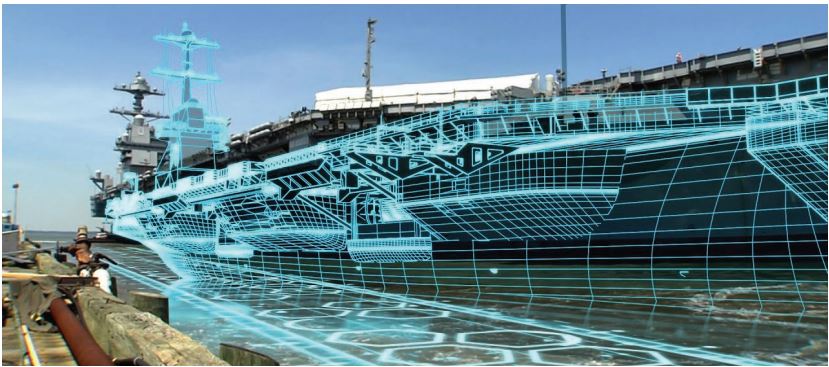

Ship design software and shipyard production software facilitate digital simulation and optimisation of shipbuilding operations and processes.

The Siemens Product Lifecycle Management (PLM) for Shipbuilding solution enables a holistic approach to optimising shipbuilding. PLM for Shipbuilding improves total enterprise collaboration, synchronisation and productivity, as well as lifecycle ship service and support, by optimising shipbuilding processes.

Ship Design and Engineering

PLM for Shipbuilding takes advantage of the latest design technology to accelerate development of modern ships and offshore platforms, driving shipbuilding innovation and facilitating global collaboration. Using ship design and engineering software, designers and engineers can create and maintain 3D models in context of key workgroups, such as major ship modules, compartments, systems and locations.

Digital Ship Construction

By deploying shipyard production software it is digitally simulating complete ship assemblies and their associated processes and can optimise process flows across the shipyard before production begins, implement lean practices at the start of new programmes and avoid the cost of building expensive physical models.

Supply Chain Management

Shipyards rely on a global supply chain of partners and suppliers to help design, develop, manufacture and test new ship concepts. PLM for Shipbuilding allows shipbuilders to exchange data reliably and flexibly with suppliers and partners, some of whom may use a different authoring tool. It also synchronises supply chain operations by ensuring the right parts are available at the right time.

Ship Service and Support

Shipyards are also focused on managing sustainability requirements and achieving continuous improvement in fleet availability, reliability and overhaul cycle reduction. PLM for Shipbuilding enables shipyards to easily develop and publish all handover documentation included in the vessel specifications and contract. Fleet owners and repair yards can better manage all maintenance and regulatory reporting requirements, service planning, execution, service processes, and metrics monitoring and reporting in a single environment/single source of knowledge.

References

1. http://www.motorship.com/news101/ships-and-shipyards/robots-pave-way-for-complex-work-at-kleven

2. https://www.researchgate.net/figure/An-automatic-lug-welding-system-with-an-overhead-type-robot-manipulator-developed-by_fig1_221979879

3. https://www.adelaidenow.com.au/news/south-australia/turning-a-new-page-in-shipbuilding/news-story/ce560750b2d230734430fc24312b13f5

4. https://asia.nikkei.com/Business/Business-Trends/Japan-s-shipbuilders-look-to-virtual-reality-for-efficiency2

5. https://3dprint.com/131892/south-korea-shipbuilding/

6. https://www.luerssen-defence.com/

7. http://www.passengership.info/news/view,carnival-monitors-cruise-fleet-from-hamburg_52193.htm