by | Prof. Dr. Md. Nor Musa | Dr. Subhashish Banerjee

“The efficiency of OTEC power plant is mainly dependent on the degree of temperature differential between the source and the sink.”

The ocean has immense potential for producing energy. Oceanic energy sources include wave energy, ocean currents, tidal energy and OTEC. Except for tidal energy, all of them are directly sourced from solar energy. Waves are formed due to the differential heating which produces wind, and these waves’ mechanical energy is utilised to produce electricity. The energy from higher water levels in high tides – the tidal energy – is also utilised to produce electricity.

Ocean currents exist due to pressure differences between two different locations in the ocean. However, in OTEC (Ocean Thermal Energy Conversion) system, the temperature difference between the warm surface ocean water (SOW) and cold deep ocean water (DOW) is utilised to run a heat engine to generate electricity. The efficiency of such electricity production power plant is mainly dependent on the degree of temperature differential between the source and the sink.

Source: Zakir Naik (2007)

Science of OTEC

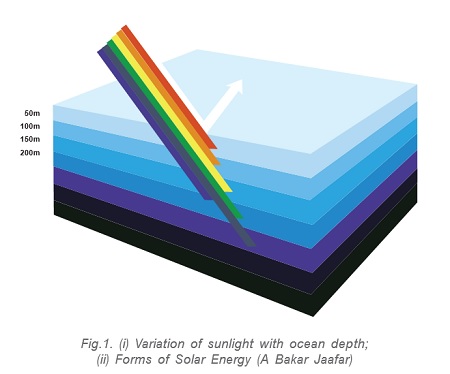

Energy resource is one of the most important criterions in the deployment of any energy system. The ocean absorbs about 15% of solar insolation, of about 1.9*1018 MJ/year. The upper layer of ocean gets insolation from the sun and is heated up. With an increase in depth, the temperature starts falling due to Lambert’s law of absorption.

At a depth of 1000 metre the temperature can be as low as 40C whereas at the surface of the ocean it may vary between 250C to 300C. The variation of sunlight penetration with depth is shown in Fig 1.

Normally, in equatorial and tropical regions the temperature of the upper layer of the ocean is above 250C, year round; whereas in the temperate region it can be lower. That is why the deployment of OTEC in the equatorial region is more lucrative than in temperate zones. The minimum 20K temperature differential between the upper-most and lower-most layers of the ocean, for the OTEC power plant to operate, is maintained round-the-clock throughout much of the year.

OTEC Technologies

OTEC power plant technologies are classified into three types, depending on the type of fluid used for their power generation.

Open Cycle OTEC

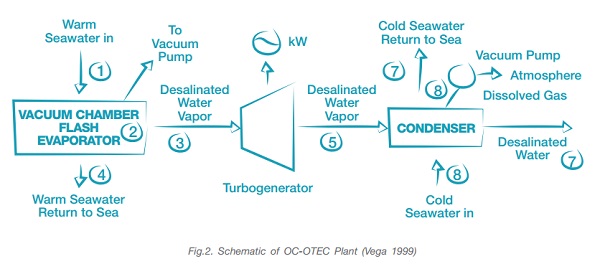

Inathe open-cycle i OTEC powereplant, warm SOW itself s used as the working fluid to run the turbine. SOW is pumped into a vacuum evaporator maintaining a pressure at 0.03 bar, at which the boiling point of water lowers down to 26.40C.

The evaporated steam obtained in the boiler is passed through the low pressure turbine connected to a generator which produces electricity. After passing through the turbine, the steam passes through the condenser exchanging heat with a 40C cold DOW. This is called open cycle because the condensate need not return to the evaporator. The condensate of the evaporated water can, however, be utilized as desalinated water. The schematic flow of such OC-OTEC is shown in Fig 2.

Closed Cycle OTEC

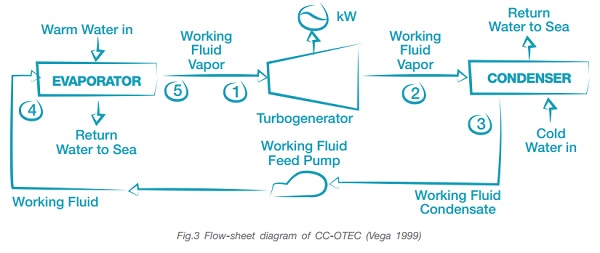

In this plant, a low boiling fluid like liquid ammonia (boiling point 33.50C at 1.013 bar and having vapour pressure 8.88 bar at 210C) is vaporized when in contact with warm SOW passed through the heat exchanger. The expanded vapour runs the turbine which turns a generator. The outgoing vapour from the turbo-generator is cooled and condensed to liquid in a 2nd heat exchanger by a cold DOW. Low boiling hydrocarbons, e.g. propane, propylene, are also considered for use as working fluids respectively. Recent advancements make use of low boiling nonazeotropic mixtures like ammonia and water to achieve better efficiency of power generation.The flow sheet diagram of CC-OTEC operation is shown in Fig 3.

Hybrid type OTEC plant

This type combines both CC-OTEC and OC-OTEC in its operations, using both ammonia and warm sea water as the working fluids. It makes steam just as in the OC-OTEC type. But to run the turbine to produce electricity, a low boiling fluid like ammonia etc. is used instead of steam. It produces desalinated pure water as a by-product alongside the power generated. However, it must be added here that the hybridtype OTEC, unlike the CC-OTEC or OC-OTEC plants, has not yet been tested for practical application. It remains a theoretical concept to maximize thermal efficiency.

On-sea and On-land trial runs of OTEC technology

In 1926 Georges Claude began research on the subject, and in 1930 built a fully-operational closed loop system OTEC in Northern Cuba which showed negative energy balance. His plant however got damaged from tropical storms. The first successful OTEC technological demonstration was achieved in 1979. It was a barge mounted CC-OTEC plant generating net power of 10-15kW, from gross power production of 50kW. It used titanium plate heat exchanger with its cold water pipes extending to a depth of 650m.

MITI of Japan sponsored a 100kW CC-OTEC plant which was commissioned in the island of Nauru in the mid-Pacific Ocean. This land-based plant was run drawing cold water from a depth of 520m, laying a 900m long pipe through the ocean floor. The cell and tube side heat exchangers were coppercoated stainless steel tubes in the evaporator and titanium in the condenser.

Freon was used as the working fluid with the trade name R-22 (Cohen 1982). The 34kW net power successfully produced from this plant since October 1981 was fed into the Nauru Electrical grid for around a year; till the entire plant got wiped out by a hurricane (Takahashi 1999). In 1993 a land-based experimental OC-OTEC plant in Hawaii successfully generated power of 210kW for five years (Vega 1999). A small fraction of the 10% steam produced in the evacuator was diverted for the production of desalinated pure water as a byproduct in the condenser, amounting to 0.4l/sec. The maximum power [gross] produced reached 255kWe, despite the plant been not optimised. A commercial optimised plant is expected to maintain the ratio of gross to net power at 0.7kW, whereas this non-optimized plant showed the ratio to be 0.5kW only (Vega 1999).

It may be concluded that OTEC is a secondary form of energy obtained from the heating-up of the ocean surface by insolation from the sun, and the gradual decrease in temperature with depth. This difference in temperature is fruitfully utilised to run a heat engine to generate electricity. Various types of OTEC designs have been considered and each of them has merits and challenges. Amongst them, hybrid types of OTEC plants seem more promising as they produce both power and desalinated water which is required in many coastal regions. However hybrid types remain theoretical concepts for the maximization of thermal energy.