Via Resource Recovery in the Wastewater Sector

by | Datuk Ir. Abdul Kadir Mohd. Din, Chief Executive Officer, Indah Water Konsortium Sdn. Bhd.

Historically, the first thought of sewage treatment dates back to the end of 18th Century when septic tanks were introduced in the West. By the nineteenth century sewage treatment methods developed rapidly to meet the needs of basic sanitation.

Today, modern and sophisticated treatment technologies are continuously developed for the purpose of protection of environmental quality in a cost efficient manner. The key driver for this trend is the increasing need for a more sustainable long term solution in terms of both the economics and the environment.

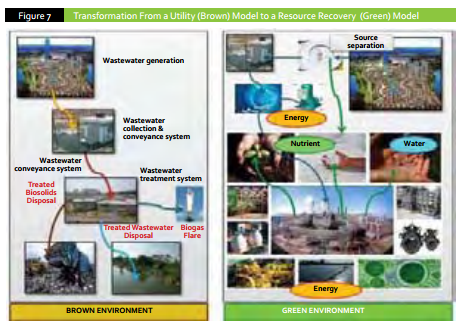

In this regard, the current practice in safe disposal of end products from sewage treatment namely, the effluent and sewage sludge, will no longer be able to meet the complex environmental challenges of climate and water sensitive futures. For this, the sewage treatment industry needs to be transformed into a resource harvesting industry. This paper describes the paradigm shift from traditional basic treatment to potential new business model via resource recovery in the sewerage sector. The key idea is utilizing the ‘Green Technology’ and ‘Zero Waste Concept’ to transform the sewerage industry into a sustainable and economically attractive model.

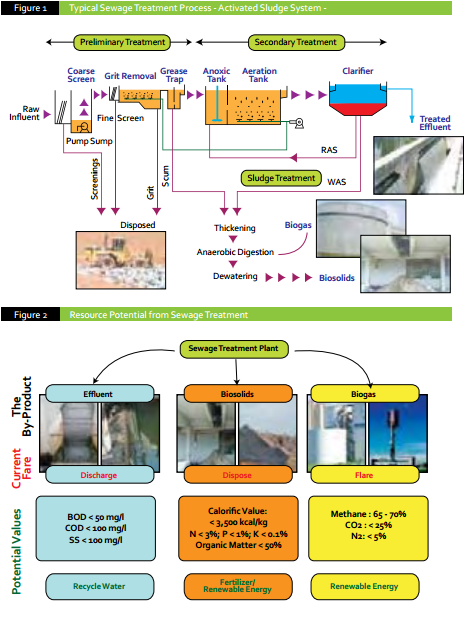

Basic Sewage Treatment

The typical treatment process flow for a modern mechanized activated sludge plant is depicted in Figure 1. Basically it involves 2 main components namely: (i) Pre-treatment for grit and grease removal; (ii) Main treatment process units where the major organic and solids pollutants are removed via Biological process (ie. secondary treatment). The secondary treatment process involves a reactor or tank for biological breakdown of organic pollutant by native sewage microbes (i.e. MLSS). This basic secondary

treatment technology produces clear effluent that can be discharged into the environment, whilst the waste sludge (WAS) is typically stabilized and dewatered into semisolid form (at 15-20% dry solid content; also known as biosolids) for disposal to landfills. If the stabilization process is involved, there is anaerobic sludge digestion and biogas is produced as well.

More recently technologies are focused on enhancing nutrient removal namely nitrogen and phosphorus as well as in reducing the operating energy requirement of systems as well as smaller foot print. The latest being a variation of Sequencing Batch Reactors, Moving Bed Bioreactor, Membrane Bioreactor, Combination of Anaerobic UASB (Upflow Anaerobic Sludge Blanket) and Aerobic systems. Although these developments produces high quality treated effluent, the waste by-products remains typically disposed unto the receiving environment.

Plausible scenarios were then created to enable the identification of technology priorities that is required to support the nation’s vision 2020.

Potential New Business in Sewage via Resource Recovery & Green Technology Application

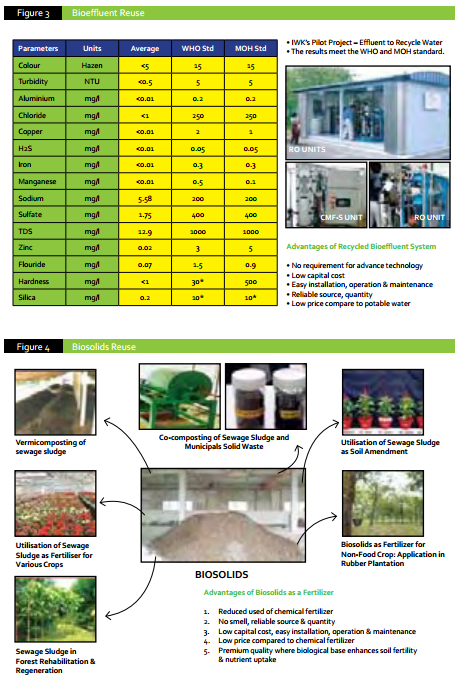

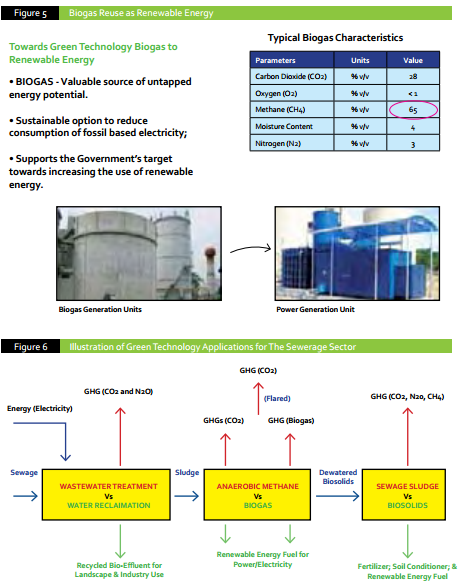

There are three (3) waste byproducts, treated effluent, biosolids and biogas that can be converted for beneficial reuse is as shown in Figure 1 whilst the potential value for reuse is summarized in Figure 2. Treated effluent can be reused for landscaping and industrial applications. Local research had identified this potential and shown that with additional downstream filtration units that can range from media based, to membrane and or RO types can produce bioeffluent for industrial uptake. An example of bio-effluent quality is shown in

Figure 3. Treated effluent without any additional treatment was also found to be beneficial to plant growth, potentially with chlorination such application can be widely and applied. Such potential needs to be realized as it will greatly relieve water stress areas and contribute towards sustainable water resources for future.

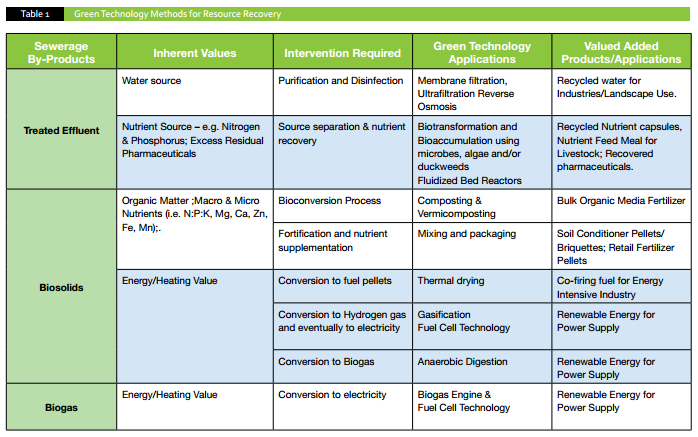

The potential benefits of biosolids reuse is far reaching. R&D studies has shown there is sufficient nutrient content in the biosolids where the typical values of N:P:K average at 3% of the biosoilds whilst its organic matter content is typically more than 50% and can contribute to improving soil conditions and nutrient uptake for plant growth (see Figure 4). The energy value contained in the dry solids is also a potential to be tapped via gasification process. Analysis of typical biosolids from IWK plants in Malaysia show the calorific value ranging from 2000 to 3500 kcal/kg.

Another potential is the energy available within biogas generated from anaerobic digestion, at 65% methane composition there is a minimum of 5000kcal/m3 of biogas being generated (Figure 5). For each of these potentials the Green Technology methods and approaches

are summarized in Table 1 and Figure 6. Green Technology is envisioned by Malaysia’s Premier Y.A.B. Dato’ Sri Mohd. Najib bin Tun Haji Abdul Razak as one of the emerging drivers of economic growth for the nation. The national Green Technology Policy was officially launched in July 2009 which defines green technology as “the development and application of products, equipment and systems used to conserve the natural environment and resources, which minimizes and reduces negative impact of human activities”. Hence technology for resource recovery for water, nutrients for soil and vegetation and renewable energy is very much in line with our national aspirations for a green economy that meets the complex demand of the impending carbon neutral and sustainable future.

Strategies and Way Forward

The application of Green Technology to produce value and material from sewerage waste by products will have the following benefits:

- Minimize discharge of treated effluent into water courses and reduce potable water stress.

- Environmental friendly outlet for Biosolids whereby disposal to landfill is avoided.

- Biogas as Cheaper source of electricity is found.

- Green house gas emissions is minimized.

- Public satisfaction is eventually achieved when the highest level environmental quality is maintained.

- Sustainable sewerage development could be achieved.

- Government to provide grant or funds to encourage 3R – for new waste minimization and recycling projects.

- Implement Pilot Projects to demonstrate the use of Green Technology for successful utilization of sewerage waste products to be implemented.

- Allocate Research & Development funds dedicated to encourage innovation in cheaper cleaner production of treated Bio effluent, fertilizer and renewable energy such as from Bio solids and Bio gas.

- Intensive and creative public awareness program to educate the public on recycling of sewerage by-products.

- Provide Policy & Guidelines for utilization of sewerage beneficial products such as treated Bio effluent, fertilizer and energy source.

- Community engagement to be encouraged via small medium industry entrepreneurship program and good incentives for Green Technology projects.

- More regional plants to be established to provide the economics of scale to generate Bio solids and Bio gas of critical mass.

- All regional plants shall be provided with anaerobic digestion for sludge treatment.

- Developer shall be encouraged with incentives to build Zero Waste plants.

- Integrated resource management to be advocated, planned and developed for implementation.

Plausible scenarios were then created to enable the identification of technology priorities that is required to support the nation’s vision 2020.

Summary and Conclusion

There is enormous benefit to be gained from the application of Green Technology to harvest the much untapped resources in the sewerage sector. For this, we need to transform the manner sewage treatment is being planned and developed in this country. Malaysia needs to leap frog our sewerage services into a zero waste, and product harvesting based on the waste to wealth model that is both environmentally and economically sustainable. With the higher vision of sewage as a resource instead of waste, the drive is to establish green technologies to produce feedstock and by-products that could be used to catalyze downstream processing to produce value added materials which have economic benefits (waste to wealth concept). In the future, it is inevitable that sewage treatment could be a lucrative business when all the stakeholders could appreciate the inherent potential in this industry. Malaysia can establish a Green Technology Hub and be a leader in this waste to wealth concept and strategize its sustainability through zero waste management.