by | Mohd Qaharuddin Abdullah, Mohamad Azreen Firdaus Abd Aziz & Siti Nur Fatimah Noodin

Introduction of National Energy Sector (Oil & Gas + Power Generation)

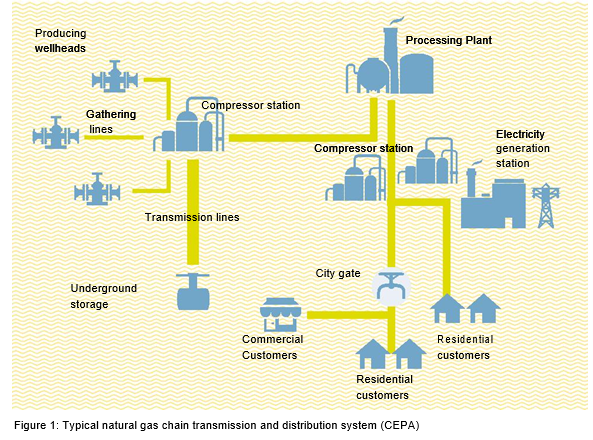

Transportation of natural gas via pipeline system is the most effective method, especially for a long distance transmission. Technically, natural gas is transported from the gas reservoir to the consumer through transmission and distribution pipelines. The transmission and distribution pipeline systems are actually different as the operating pressures and the pipe sizes are different.

A transmission pipeline transports the natural gas from the Gas Processing Plant (GPP) to the distribution center and to larger volume customers. This transmission pipeline ends at the city gate station and transports the natural gas within the storage field. A distribution pipeline supplies and distributes the natural gas from the city gate station to the end-users. Normally, the pressure of the natural gas would be reduced and the gas is odorized for safety purpose at the city gate station.

Overview on the Peninsula Gas Utilization (PGU)

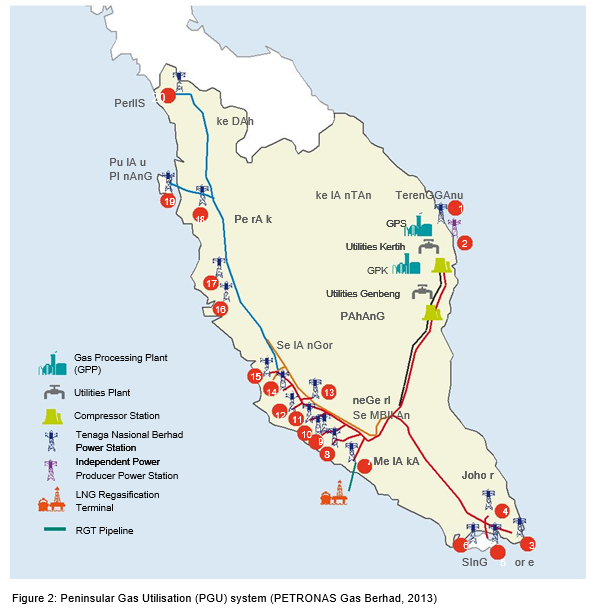

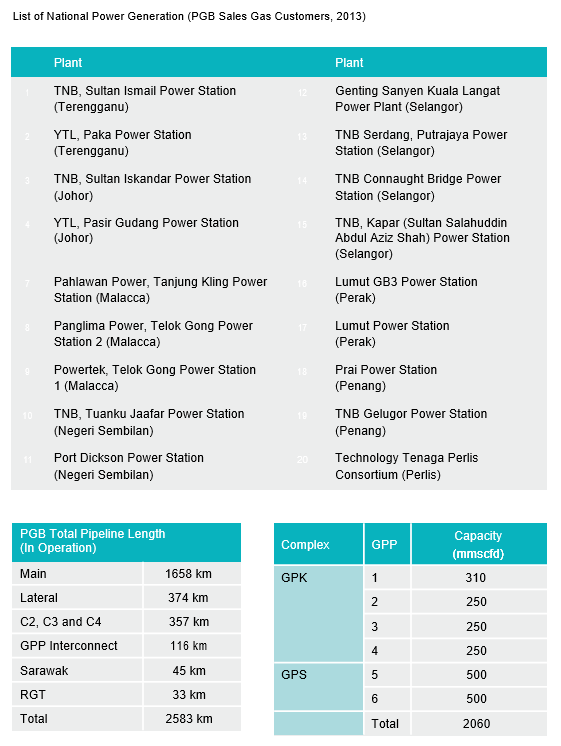

Approximately 2583 km of high pressure natural gas transmission pipeline in the Peninsular Malaysia is solely managed by PETRONAS Gas Berhad (PGB). This natural gas transmission pipeline, known as Peninsular Gas Utilisation (PGU), serves as the backbone of Peninsular Malaysia’ natural gas supply infrastructure with the pipes ranging from Nominal Pipe Size (NPS) 2 up to the 48. The pipelines are operated and maintained by the operating division, Transmission Operations Division (TOD) of PETRONAS Gas Berhad (PGB). This PGU infrastructure comprises six gas processing plants with a capacity of 2000 million standard cubic feet per day (mmscfd). The handling and maintenance activities of the transmission pipeline are carried out in the stipulated region along the four phases through the Pipeline Integrity Management System (PIMS) programs.

Technically, the natural gas utilized in the National Gas Power Generation is supplied by the PGB through the PGU system which is connected to the Power Generation facilities. Currently, there are 20 major local power generation plants and two located in Singapore – Senoko Energy and Keppel Gas – that receive the natural gas through the PGU system supplied the PGB.

The infographic shows the industrial relationship between the oil and gas industry and the national power generation industry. The natural gas transported to the power generation would be used to generate electricity through the combustion process. The amount of electricity generated depends on the features and capability of the power generation infrastructure. Generally, the exhaust gas from the combustion process will drive the turbine which is connected to the generator based on the principle of energy conversion and multiple engineering technologies. Electricity generated in the generator is transferred to the transformer where the voltage is increased. The electricity is then transmitted to the switchyard and delivered to the communities via the National Grid System.

Corrosion normally occurred on pipes that are made from the carbon steel material due to the presence of Carbon Dioxide (CO2) and Hydrogen Sulphide (H2S) in the constituents of natural gas

Ensuring a Security Supply: Pipeline Maintenance & Operation

Pipeline facilities are exposed to the environmental influences and loading factors that could reduce the integrity of the pipes. Furthermore, as the time elapsed, this pipeline aged and become prone to various types of physical flaws such as corrosion, stresses and mechanical damage. These physical flaws may cause leakages that lead to failures of transmission operation as well as the power generation process, production lost and catastrophe destruction which ultimately will cause negative impact towards the environments, health and safety.

It is reported that corrosion is the major factor of the pipeline failure. Based on the statistic of 2008, 23.3 % of natural gas pipeline failures are due to the corrosion. Corrosion normally occurred on pipes that are made from the carbon steel material due to the presence of Carbon Dioxide (CO2) and Hydrogen Sulphide (H2S) in the constituents of natural gas. The existence of these hydrate components initiates pipeline internal corrosion such as cavitation, pitting, galvanized, stress cracking corrosion and erosion through the chemical and physical process, and will contribute to the metal loss of the pipeline thus reduces the pipe wall thickness.

Electricity is an important commodity. Defective pipeline may cause the disruption of electricity supply which may lead to hardship to the population, hinder economic activities and paralyze the industrial sector. Continuous supply of electricity is important. Therefore, maintenance of the pipeline system that transports the natural gas – the source of electricity – should be prioritized in the gas supply operation.Pipeline system maintenance is necessary to ensure good integrity of the pipeline system, prolong the life of the pipeline and to ensure the safety of the natural gas transportation operation. There are various techniques applied in the pipeline maintenance activities such as pipeline pigging, Right-of-way (ROW) and site maintenance, pipeline repair and pipeline segment replacement.

Pipeline pigging is a technical maintenance of the transmission pipelines by the application of the Pig tool propelled through the internal pipeline. Pipeline pigging is operated in every phase of pipeline’s life, during the pre-commissioning, commissioning and operation. Operational pigging is implemented on active pipeline to clean up the debris and to inspect the integrity of the pipeline.

State of the Art: Intelligent Pipeline Inspection Gauge (PIG)

A Pig tool that performs advance tasks on monitoring the integrity of the natural gas transmission pipelines during the pigging operation is commonly known as an Intelligent PIG. Basically, Intelligent PIG is referred as In Line Inspection (ILI) tool and it is operated to obtain specific information related to the pipeline integrity. The integrity of the pipeline ‘in service’ is normally inspected by the Intelligent PIG tool since it is based on the Non Destructive Test (NDT). NDT approach is more preferable for the oil and gas pipeline inspection since this method does not disturb the normal operation of the pipeline. The primary purpose of the Intelligent PIG is to detect the pipeline anomalies and to determine the size of the defects detected on the pipeline. Technically, an Intelligent PIG tool is launched through the natural gas transmission pipeline and it flows along with the product to monitor the integrity of the pipeline.

The primary purpose of the Intelligent PIG is to detect the pipeline anomalies and to determine the size of the defects detected on the pipeline

Technology Foresighting Driven

The design function of Intelligent PIG is more sophisticated as the structure of the PIG device consists of sensors, a battery, electronic components and a recording device which are incorporated and embedded together in a genuine inspection tool. The electrical energy of the electronic system is provided by the battery. The data storage is installed in the Intelligent PIG to record data measurements to be further analyzed after the pigging operation is completed. The function of the odometer wheels is to indicate the distance the device has traveled as well as the location of the defects detected in the transmission pipeline system. The main function of the sensors is to make assessment as the device travels through the natural gas transmission pipeline.

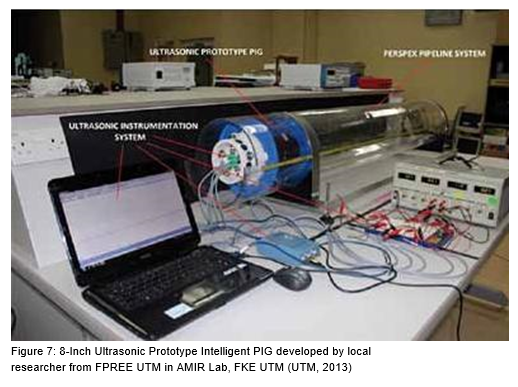

The application of the inspection tool depends on the technology of its sensor. Different type of sensors performs different functions on the pipeline inspection. The Intelligent PIG that utilizes the Electromagnetic concept is known as Magnetic Flux Leakage (MFL) PIG and Eddy Current (EC) PIG, whilst the Intelligent PIG that utilizes the ultrasonic concept is named as Electromagnetic Acoustic Transducer (EMAT) PIG and Ultrasonic PIG. An Intelligent PIG that is designed with proper consideration to criteria such as pipeline medium, pipeline features, pipeline characteristics and the goal of the evaluation process, will have high capability to perform the integrity assessment of the transmission pipeline system as well as addressing a security supply of the natural gas.

The application of high technology instrumentation system in the development and construction of the inspection tool with special consideration on microprocessor development, material of device, battery technology, and high sensitivity of the sensor measurement for the robust application and operation in the life natural gas transmission pipeline system is enabled through the extraordinary work and the practical output of research and development.

Positive growth on the research and development work, specifically on the Non Destructive Test (NDT) application, would enable the development and construction of tools with a wide horizon of inspection capability on the multi-diameter pipeline, challenging subsea

Spearheading on the Research & Development

It has to be emphasized that, this PGU facilities need to be maintained appropriately according to the technical standards and regulations. Technology optimization of the Intelligent PIG is very essential in order to upgrade the inspection tool to further evaluate the pipelines integrity in a very intelligent algorithm and thus anticipate the potential threats on the national natural gas transmission pipeline system. Significant contributions in the Research and Development work is needed from various parties such as industrial and academia research institution, pipeline operators and services etc. Positive growth on the research and development work, specifically on the Non Destructive Test (NDT) application, would enable the development and construction of tools with a wide horizon of inspection capability on the multi-diameter pipeline, challenging subsea pipeline and high flow rate medium and non-piggable pipeline, thus ensuring a security supply of natural gas for the national power generation.