by Dr. Ibrahim Abu Ahmad | Senior Associate, MIGHT

After been watching many sci-fi movies on robots, androids and humanoids like the Ex-Machina, Spare Parts and The Avengers: Age of Ultron, some of us may dreaded the moments where these artificial intelligences would one day “control” and turn against their own creators. Others may view otherwise and look forward with great expectations. Their existence is inevitable as we progress technologically. They would become the new normal to have amongst us, humans. Not only would they impact the way we live, work and play, they may even dictate how we should behave and adapt to the new

way of life.

This sci-fi thing should get us thinking about the distant future. The future where the world would be technologically sophisticated and highly complex. The world will be so wired up. It will also be so integrated, physically and digitally, that we would find it difficult to separate and differentiate between “what is real” and “what is not”. The mantra of this new technological era will be “convergence”. The convergence of the physical and virtual technologies that would either be a blessing or a nightmare to some. It could either simplifies or complicates matters. Depending on their applications and the intended usage, it could be a boon or doom.

The beginning of such a journey towards a new technological age or revolution is evidently apparent with the announcement at the World Economic Forum (WEF) Conference in January 2016. The Conference has ignited a profound interest on the dawn of the “Fourth Industrial Revolution” or commonly known as “Industry 4.0”. It’s now on everyone lips, so to speak. Hotly debated at the international and regional fora, many so-called pundits and scholars have been offering their own thoughts, interpretations and prescriptions of what exactly the world should expect and react, and why should we as a global community cares its coming. Hopes also run high among the developed and advanced economies that are technologically ready or fully equip to take advantage of or to be the potential beneficiaries of the new revolution. The less technology advanced economies,

not wanting to be left behind, are busily preparing themselves too in joining the race.

But some contended that this intensely debatable topic: “Fourth Industrial Revolution” or “Industry 4.0”, is not entirely fresh or new. It has been around since 1940, based on a document titled “America’s Last Chance” by Albert Carr. Some were of the views that it has been made new or re-born by the WEF boss, Prof. Klaus Schwab. Using it as the central theme of the WEF 2016 Conference, he made it clear to the global business leaders, heads of state, public intellectuals, and NGO’s on the dawn of the new industrial revolution. So 2016 is the year that make public on the arrival of the industry 4.0., soon to replace industry 3.0. that emerged about four decades ago.

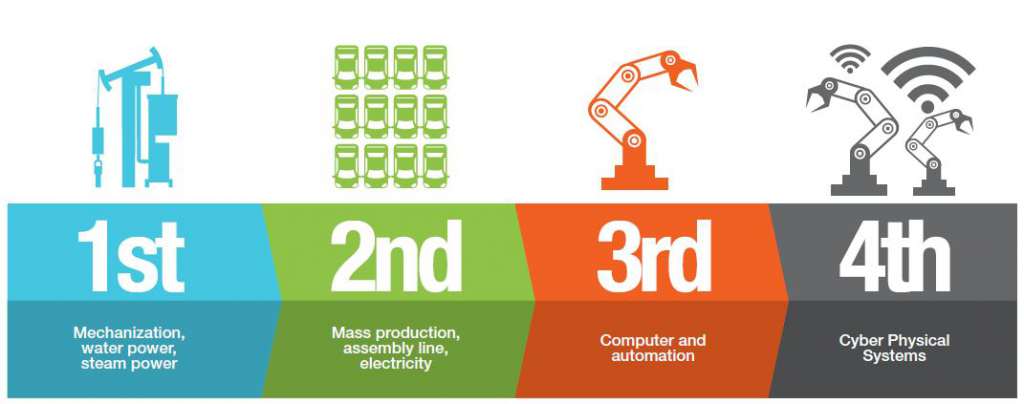

According to Schwab, the First Industrial Revolution that began in 1784 has benefitted mankind greatly through the introduction of the steam engines and mechanized production processes to the world. Close to a century later, the electric

power and mass-production processes were introduced and this period was then known as the Second Industrial Revolution. The Third Industrial Revolution saw the entrance of the digital technology and “now a Fourth Industrial Revolution is building on the Third” and “characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres”, as argued by Schwab. All these past industrial revolutions are fundamentally transformational in nature. They have huge impacts on the humankind, socially and economically. In other words, they have revolutionised and

transformed the global economy and brought immeasurable benefits to the humankind. At the same they have caused havoc

and irreversible damages to our blue planet, earth.

Coming closer to home, we also have readily accepted the advent of industry 4.0. As reported in “2016 GE Global Innovation Barometer” recently a “significant number of Malaysian executives are more positive about entering the fourth industrial revolution as compared to their peers globally.” Though globally, the U.S., Germany and Japan remained as the top three leading innovation champions, surprisingly Malaysia, together with other

countries such as Australia, Canada and Switzerland, emerged as one of the new entrants to the list. This is a piece of

good news for the country. But the GE Global Innovation Barometer survey reported that the Malaysian businesses only

favoured incremental innovation and internal innovation in terms of their innovation strategy, quite a stark contrast to their global peers. It is also revealed talent remained the main challenge for the country. However, Malaysia’s future productivity growth is highly dependent on the capability of the workforce to innovate and apply advanced knowledge and technologies. The issue of human capital development is critical to ensure long-term sustainable economic growth and development.

We have our Third Industrial Master Plan 2010-2020 (IMP3) and the new STI policy (2013- 2020) to assist and to propel the country into the new era of industry 4.0. IMP3 has been executed half way now and the new STI implemented about 3 years ago. But none of the Plan and the policy documents have specifically mentioned about preparing or building the country’s

economy based on industry 4.0 though undeniably there are some elements or dimensions in these two documents reflecting such move towards it. For example, in IMP3, it’s about going for transformation. Since the theme of IMP3 was “Malaysia – towards global competitiveness”, it reflected the country’s natural progression and its next destination of becoming a high

income and advanced economy by 2020 through greater utilisation of technology and heavier emphasis on product or process

improvement via R&D.

Looking back on the performance of first two industrial master plans, IMP1(1986-1995) has laid down the foundation for the development of the manufacturing sector, which became the leading growth sector of the country’s economy. IMP2 (1996-2005) with its two key thrusts, “manufacturing plusplus and cluster-based industrial development”, has somehow deepened the development of the manufacturing sector which led to increased value-added activities, enhanced productivity, greater industry linkages as well as growth of manufacturing related services. Now IMP3 aimed to improve the country’s global competitiveness by moving the economy up the value chain beyond the “middle development” stage to a more productive, value-added and knowledge intensive stage.

We can see that the period of IMP1 is akin to the era of second industrial revolution with mass production at its core. While the period of IMP2 sort of reminiscing the age of third industrial revolution with greater automation and rising application of the digital technology. These industrial transformations in the last three decades is currently being spiced up with a tinge of industry 4.0. Advanced intelligent (AI) and robotics, cloud computing, the internet of things (IOT) and the like, including advances in biotechnology are some of the areas that are actively been ongoing in the recent years.

Similarly, the new STI policy put emphasis on the importance of science, technology and innovation (STI), particularly in facing the rapid changes of a globalised and competitive world. Realising that innovation-led growth is central to propel the nation forward, it is imperative that STI be strengthened and mainstreamed into all sectors and at all levels of national development agenda. The clarion call by our Prime Minister at Global Science International Advisory Council (GSIAC) in London recently spoke highly on the needs for the country to be industry 4.0 ready. This call was reiterated at the recent National Science Council (NSC) Meeting in August 2016. The new STI Master Plan, now on the drafting table, will be without doubt, incorporate the industry 4.0 elements. For sure, the new STI Master Plan will be transformational and a game changer too. More importantly, the Plan’s prescriptions should be “characterized by a fusion of technologies that is blurring the lines between the physical, digital, and biological spheres”. Nothing less, we should expect.

On the state of country’s readiness, it is self-evident, based on its international competitiveness, as depicted by the diagram below. The government welcomes suggestions on how best to facilitate more manufacturers to automate and embrace the fourth industrial revolution in relation to tax incentives. In the recent MITI dialogue with the Federation of Manufacturers of Malaysia (FMM), it was reported that most manufacturers are aware of the Industry 4.0 concept, but only 30 per cent have started to invest and leverage on modern technology. If Malaysia is to compare itself with countries in terms of high-tech exports, the country was ranked 11th in the world in 2014 with USD63.38billion. The top three global exporters of high-tech were China (USD558.61b), Germany (USD199.72b) and Hong Kong (USD192.72b). Our neighbour, Singapore, was ranked fifth, after USA, at USD137.37b. In this respect, Malaysia has made a remarkable progress in the high tech industries with the help of foreign direct investments (FDI). But then again some people would say that a major portion of those exports tho ugh “Made-in Malaysia,” they are not actually “true Malaysian” products. Most of them are made by or for MNCs in the country. Our former Prime Minister, Tun Mahathir, was among those hard critics. However, others would argue otherwise. They contended that we should be proud of 0urselves since we have shown our capabilities in making those hightech products through our own

ugh “Made-in Malaysia,” they are not actually “true Malaysian” products. Most of them are made by or for MNCs in the country. Our former Prime Minister, Tun Mahathir, was among those hard critics. However, others would argue otherwise. They contended that we should be proud of 0urselves since we have shown our capabilities in making those hightech products through our own

skilled-labour force. We should bear in mind that high-tech exports are products of high R&D intensity such as in aerospace, computers, pharmaceuticals, scientific instruments and machinery.

Admittedly, we are already entering the path of the fourth industrial revolution. However, reflecting on the recent past growth performance of the country, there is no denying that Malaysia has continued to perform below its potential since the onslaught of the Asian Financial Crisis. It failed to achieve the sterling pre-Crisis growth of over 8 per cent per annum. Post Crisis growth rate has just been averaging at 5.5 per cent annually. Arguably, as the economy matures, one would not expect it to grow faster

anymore. Around 4 to 5 per cent growth will be the new norm for the country, others opined.

Nevertheless, one of the greatest challenges currently facing the country today is how to facilitate greater involvement of the private sector in driving economic growth in the age of Industry 4.0. Today we continued to witness some volatilities in world trade. Growth in world trade is predicted to be at 2.8 percent this year, lower than previous forecast of 3.9 percent by World Trade Organization (WTO). The same goes to the global banking and monetary systems which are still on the mend since 2008 Global Economic Crisis. The impact of the global crisis is felt even today and is affecting Malaysia’s growth outlook and exports through the country’s exposure to the world economy via trade. This is quite a worrying situation since the manufacturing sector accounts for 75 per cent of the country’s exports and 30 per cent of GDP and employment. If services and other sectors are taken into account the overall impact will be much greater.

Another big challenge for the country is that it aspires to become a high income country by 2020, a matter of five years down the road. Though the private sector has been identified as the primary engine of economic growth, a key challenge remains: How to get the private sector to be the real engine of growth in the fourth industrial revolution? It’s important contribution to new job creation, sustainable economic growth, creation of a new breed of entrepreneurs, and the development of a new economic landscape is beyond doubt. But the country must ensure that it is truly happening.

In the current economic uncertainties, the building blocks for the country’s new industry 4.0 would initially needs to “stress more on an economy than could reduce the country’s vulnerability to the global economic crisis.” Within the scheme of the building blocks all angles must be covered. Ultimately, it should match perfectly with the 1Malaysia concept, a guiding principle to build a united and progressive Malaysian nation in the 21st century and beyond, as stated in the 11th Malaysia Plan. Its significance was once echoed by Prof. Edward C. Prescott, a Nobel Prize winner in economics and a member of the World Bank expert team, who was quoted to have said that “while the country was moving up, it needed the commitment of the people.” A daunting task though. Yet it’s workable, if we can rally the consensus of the people with the full commitments of the private sector. If that happens, Industry 4.0 is within our reach folks!

1 GE’s Global Innovation Barometer is an international survey which takes place across 23 countries, gathering perceptions of innovation in the world today. The recently compiled fifth edition of the barometer gathered insight from over 2,700 innovation business executives and nearly 1,350 innovation educated members of the public to deliver a comprehensive report on the global perception of innovation.