by | Abd. Rahim Abu Talib, Ph.D, Chief Operating Officer, Aerospace Malaysia Innovation Centre (AMIC)

Awareness regarding the need to have a sustainable future has been discussed and debated in many international forums among the government agencies, non-governmental organisations as well as private industries.

Many initiatives have been planned and implemented in the past decades to ensure the modern development in high end technology will lead to a sustainable way of life in the context of social, environment and culture.

Aerospace industriesin particular have played a major role in contributing to the fast development in today’s modern life. The direct and indirect impact from the aerospace industries, along the value chain from processing raw materials, design, fabrication, manufacturing, assembly, installation, application, and maintenance until the end of life of the components, does play a role in affecting the modern development. Green Aviation Summit 2010, organised by NASA AMES Research Centre, put up challenges for green aviation and focussed on the environmental impact of aviation. Noise and emissionsreduction, fuel burn reduction, alternative fuels and environmentally friendly airspace operations were among other issues being discussed and presented.

Aerospace Malaysia Innovation Centre (AMIC), a standing research institute of excellence established in November 2011, is actively focusing its efforts on the three areas which have been labelled as ‘research roadmaps’ in order to tackle some of the current most important challenges and helps to set up the pathway for the future aerospace industry. These research areas consist of jet fuel production from microalgae, innovative manufacturing of aerospace composite structures, and advanced green materialsfor aerospace (Fig. 1). Continuous and dedicated research in these fields will provide AMIC with an international recognition of its expertise in working towards sustainability of the aerospace industry

Since the launch of the National Aerospace Blueprint (1997) which emphasized on the importance of aerospace industry towards globalization and on the value chain of production, Malaysia has a clear pathway towards a sustainable future in aerospace industry through highly competitive research activities. AMIC is a unique research innovation centre that assistsresearchersin the industry and universities to expand and potentially be the benchmark for the whole wide aerospace research in near future. This article will provide a brief overview of AMIC initiatives towards green and sustainable aeronautics.

Jet Fuel from Micro Algae

The Need for alternative to Fossil Fuels

There is a general consensus within the literaturethat fossil fuel feedstock used for the production of aviation-grade kerosene fuel are dwindling. Koh and Ghazoul (2008) expect a peak in oil production scenario within the years 2010-2020, assuming that global oil consumption increases from 85 million barrels a day in 2006 to 118 million barrels per day in 2030. Nygren et al. (2009) projected that civil aviation traffic growth will increase at a rate of 5% per year, while fuel consumption will increase at 3% per year. Lee et al. (2009) however projected that aviation traffic growth will increase by 4.5% to 6% per year over the next twenty years, with traffic doubling every 15 years. It is projected that the rate of discovery of new feedstock for petroleum will drop significantly by the middle of the twenty-first century (Daggett, et. al, 2007), and that current production trends will be unable to meet future demand for fossil fuels. Despite the improvements in aircraft fuel efficiency since 1960, further efforts need to be made in order to mitigate the dependency on traditional fuel sources and to replace current petrol-based fuels. Furthermore, there is an increasing need for independent energy security among oil-importing countries, due both to fluctuating oil prices as well as the finitude of oil reserves in oil-producing countries.

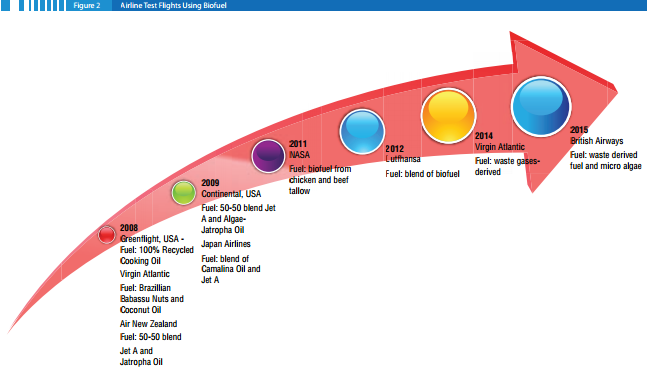

There have been several test flights by airlines in partnership with aircraft and engine manufacturers to determine the performance of their planes using biofuel, in either a 100% or 50-50 blend capacity. Figure 2 shows some of the test flight made by various airlines using blends of biofuel.

What is Microalgae?

Algae fuel is a natural alternative fuel in replacing the scarcity of fossil fuel. Microscopic algae, or microalgae, which does not have roots, stems or leaves can easily be found in freshwater and marine systems, has been identified as being the most promising and the only source that could potentially produce biofuel in the quantities that are needed (Hu, 2012). Currently, biotechnologists and researchers from various institutions are actively conducting vast research in extracting the lipids (oil) from microalgae in production of biofuel for diesel engines. These research activities are being closely followed with keen interest by aviation companies including European Aeronautic Defence and Space Company (EADS) that identified algae had been identified as an economical source for future of jet fuel. This was highlighted by Mr Louis Gallois (past CEO of EADS) during his visit to Malaysia in April 2012. Last year European airlines, biofuel producers and the EU Commission signed a pact aiming to produce two million tonnes of biofuel for aviation by 2020.

Some of the reasons for the selection of microalgae as an alternative for jet fuel are:

- Algae fuel has minimal impact on fresh water resources and is relatively harmless to the environment.

- Algae can help to reduce the CO2 emission.

- The entire algal organism uses sunlight to produce lipids or oil, hence beneficial in producing mass capacity of fuel.

- Unlike other fuel alternative such as soybeans, algae can easily grow wherever there is fresh water and converts carbon dioxide into carbon-chain molecules (in producing oil) very quickly and efficiently.

Future research work is expected to focus on the establishing of conditions for a sustainable production of jet-fuel from microalgae in Malaysia, dedicating specific efforts on some hardpoints such as algae strain selection (oil extraction and oil conversion) and improving the global production chain through follow-up of the technical, environmental and economical balances of the microalgae pathway.

Innovative Manufacturing

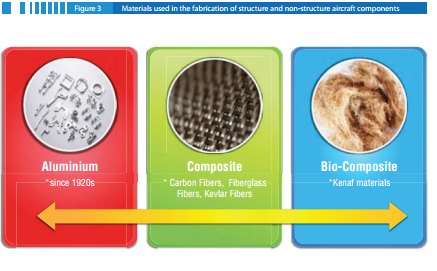

Malaysia aerospace industry should concentrate its efforts on the innovative manufacturing of aerospace composite structures and producing lighter aircrafts. As lighter aircraft consumes less fuel, the increase use of composites in air crafts structures (50% of the structure in the A350 for example) is the most effective way to reduce fuel consumption. Malaysia is already playing a very important and active part in manufacturing and supplying of composite materials for international aircraft builders. Composite Technology Research Malaysia (CTRM) which, in volume, is the fourth composite part provider of Airbus. Figure 3 shows the development of different types of materials used in the aviation industry. The manufacturing of such new advanced materials requires intense research and development.

Advanced Green Materials

Materials for Gas Turbine Engine

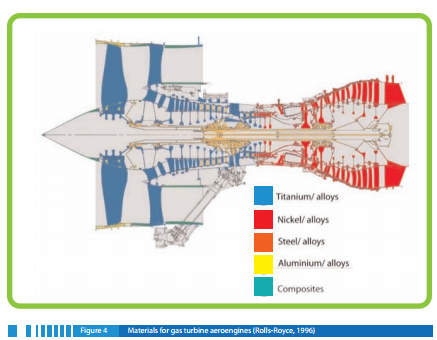

It is known that both thermal efficiency and power output are influenced by the maximum cycle temperature and pressure ratio of the gas turbine engine. Broadly speaking, the maximum temperature has a more important effect on the power output whereas the pressure ratio has greater influence on the thermal efficiency (Endres, 1973). Thus, the use of new materials with high temperature withstanding capabilities is likely to improve the thrust-to-weight ratio of the aero-engines. For aero-engines, materials are chosen to satisfy the lightest design that technology allows for the given loads and temperatures prevailing. Figure 4 illustrates the use of different materials in gas turbine aero-engines.

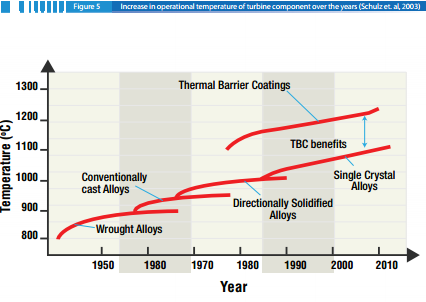

The quest for more efficient gas turbines has been constantly motivated by the perpetual developments in a wide range of engineering fields including turbine design, combustion analysis and structural ceramics. Figure 5 shows the increase in operational temperature of turbine component over the years (Schulz et. al, 2003).

The performance of the gas turbine can be enhanced by increasing the Turbine Inlet Temperature (TIT) thereby improving the thrust to weight ratio while minimizing the specific fuel consumption. Thermal Barrier Coatings (TBCs) are used to improve the gas turbine efficiency by either increasing the turbine inlet temperature at the present metal temperatures or by reducing the coolant requirements while maintaining the current turbine inlet temperatures. Additionally, the life of the component can be extended. Thermal Barrier Coatings are also being used in other components of the jet engine such as in combustors, liners and hot gas impingement protection on stationary components.

Furthermore, current aircraft cannot fly in ashes because the turbine blades would be blocked due to their structure with the actual TBC. To overcome such shortcomings; another reliable Thermal Barrier Coating material is required. Up to now, silica aerogel has not been investigated as a Thermal Barrier Coating material and therefore a positive result of this research will attract aerospace industries in many ways. Maerogel has been invented in Malaysia by Professor Halimaton Hamdan, in 2008 and has a cost reduction of 80% in its production compared to the traditional silica aerogel.

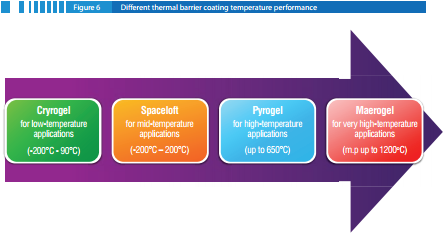

Aerogel is accepted as one of the best insulation materials by most industry experts as it can hold high temperature – up to 3,000 Fahrenheit. Aerogel is also accepted as a very good sound-proofing material, and known as the lightest solid material. It is extremely porous and very low in density. Hence, aerogel makes good thermal insulator. There are a few types of aerogel such as cryogel, spaceloft and pyrogel (Figure 6). As the cost of production for aerogel is expensive, Malaysian researchers are trying to develop a new aerogel from rice husk as a substitute material to reduce the cost of production. Eco-efficiency is a key to address aerospace industry sustainability and environmental impact.

A significant part of eco-efficiency relies on the use of new greener materials. This innovation of the new Malaysian aerogel from the rice husk is known as Maerogel. Maerogel is advantageous for the aerospace industry because:

- Its quality is superior compared to current aerogel.

- It is environmental friendly as the basic ingredients are from rice husk.

- It uses cheaper alternative material – rice husk.

- It provides better insulation compared fibreglass.

- It is nanocatalyst.