by | Noor Asha Bin Abdul Rashid

Author’s Profile

Mr. Noor Asha graduated with B. Eng (Hons) in Mechanical Engineering (Marine Technology) from Universiti Teknologi Malaysia. He started his career as a Mechanical Engineer with the Sime Sembawang Engineering, in 1993. In 1995, he started the journey as a Class Surveyor by joining Lloyd’s Register (LR), involved in the Classification & Statutory Surveys of ships in operations, new ship constructions, pressure vessels and other industry related inspections. He was part of the project team for the construction of 2 MISCLNG ships ( GTT No.96 membrane Cargo Containment System) at MHI Nagasaki in 2002~2003.

He joined BV in 2004 as Senior Marine Surveyor and was sent to South Korea in June 2006 as the BV Project Manager for construction of 3 MISC LNG ships (GTT Mark III cargo containment system) at Samsung Heavy Industries (SHI) at Geoje, Korea and 2 MOL LNG ships (GTT III with DFDE engines) at Hyundai Heavy Industries (HHI) at Ulsan and Mokpo, South Korea from 2006~2009.

Upon returning to Malaysia in July 2009, he was entrusted to be incharge of all BV new shipbuilding projects in Malaysia and was promoted 2 years later as the New Construction Manager for BV Malaysia.

He is a Chartered Engineer (C.Eng) with the UK Engineering Council, a committee member of the MJB RINA-IMarEST since 2010, Hon. Treasurer of the MJB (2012~2015) and a Fellow of RINA (UK).

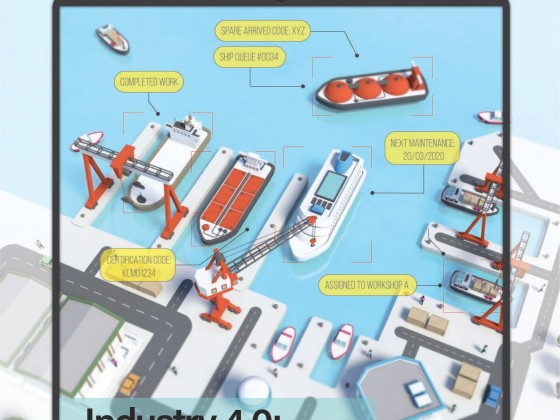

These past few years have seen a steady introduction of technological advancements in the manufacturing environment. Industry 4.0 is helping to reinvent the sector with datarich, streamlined and efficient smart production processes with the increasing rise of ‘smart factories’. Within this shift, new technologies such as IoT, Cybersecurity, big data, virtual reality, cloud computing and autonomous robots are slowly making their presence felt in the manufacturing industry. The ship building and ship repair (SBSR) industry is also poised to follow the same trend in embracing Industry 4.0.

Industry 4.0 In The Shipyard

The benefits of implementing Industry 4.0 technologies in any industry, specifically in the SBSR industry are very encouraging—it is projected to reduce 50 percent of execution time, lower engineering costs by 30 percent, and provide up to 50 percent higher throughput across a particular organisation.

Thus, the potential of Industry 4.0 cannot be ignored. It is vital for the SBSR industry to join this revolution in keeping pace with the competition and demands of the industry across the entire lifecycle of the ship building–from design to its decommissioning or scrapping.

Whilst the design and construction activities can be integrated with Industry 4.0 technologies in a straightforward manner, the operational activities will require a different approach or treatment. The appropriate name can be Shipping 4.0 and will encompass amongst other topics such as:

♦ Lower OPEX: less crew, improved fuel efficiency, reduced maintenance.

♦ Improved safety: lower probability of human failure, less crew exposure to hazardous situation.

♦ Reduced environmental impact: emissions, probability of spills.

♦ Fleet management optimisation (Asset Integrity Management)

♦ Cyber-security

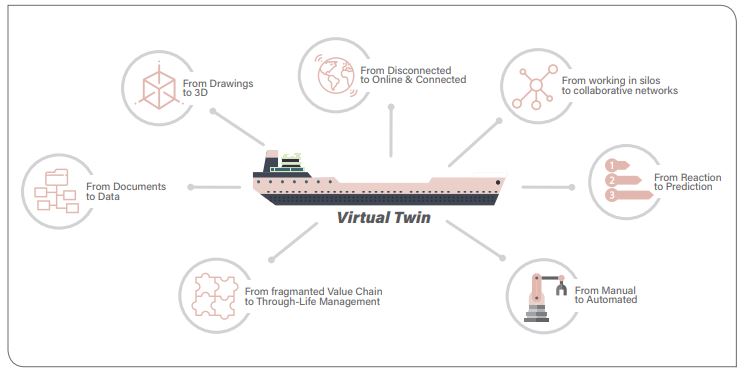

Design Appraisal With Digital Twin

An example of the Industry 4.0 application in the SBSR industry are tools developed by Bureau Veritas to support the aspirations of Industry 4.0 and Shipping 4.0. Known as Digital Twin, it enables a design appraisal of plans and documents to ensure accuracy and ensure efficiency in all aspects of ship building.

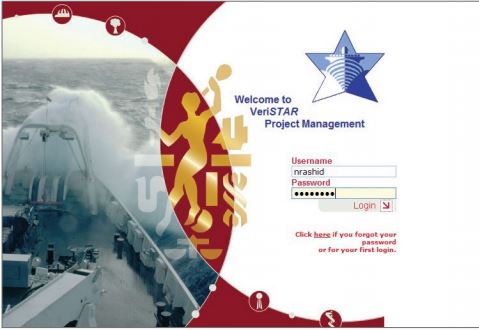

VERISTAR Project Management (VPM)

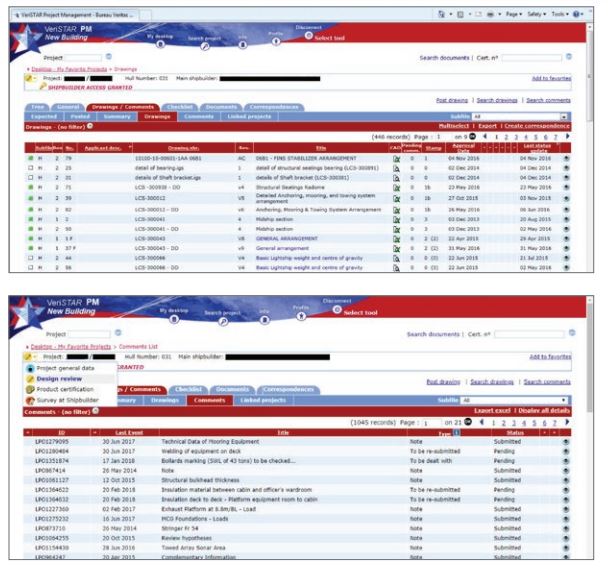

Bureau Veritas designed a project management tool named VERISTAR Project Management (VPM) due to an increasing number of stakeholders involved in new construction activities, multiplicity of rules and regulations and client request for transparency in all related activity. A web-based collaborative platform for project management, all stakeholders can review and exchange information during the project lifecycle—such as design review, product certification and survey of construction. All data is available online in real-time through a single tool and a centralised database for the internal project team (project managers, surveyors, administrative staff) as well as external clients (shipyard, ship owner, manufacturers/suppliers). For each project, based on the contracts, the system can identify and generate all project actions. The project manager, based on additional clients’ requirements and/or specific conditions, may customise the project. The project manager will have ownership of the tool to manage the assignment of different actors and follow up of the process. When using VPM, access to the projects’ files, status of design review, product certification and survey of construction is available to authorised persons through a personalised desktop. Meanwhile, access to comments and their status are subject to a previous agreement between the three concerned parties (shipyard, owner, Bureau Veritas).

Design Review

All drawings submitted by shipyard/designer, either through the system (e-drawing) or by mail, are individually identified by incoming/outgoing references and its approval status. During the review process, all comments on drawings transmitted to shipyard/ designer, are identified within the project and will be followed until a final decision has been reached. All required drawings are clearly identified and indicated once the review has been completed.

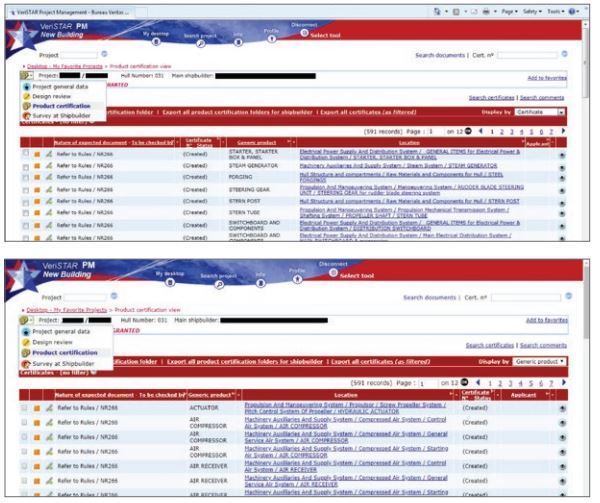

Product Certification

For each product (material, equipment) that is subject to product certification, an individual file is created. The file contains definition of the product as well as the rules/requirements. The certification may be initiated either by the project manager by assigning the relevant BV Centre or the local office when informed by the manufacturer/supplier. In case the products are subject to design review, then it will follow the same procedure as for the ship’s drawing. During the procedure, the different milestones may be indicated, periodical report issued and at the end an electronic certificate is issued.

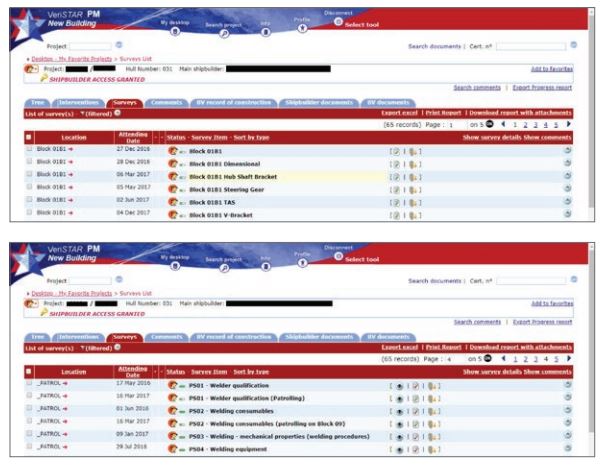

Survey Construction

The system identifies all surveys and actions to be carried out. The status of attendance as well as eventual comments (by the attending surveyor), issued to the attention of shipyard, is registered in an individual file. For follow up purposes, comments including design reviews are available in a dedicated view. The handling of comments follows the same procedure as in design review. Unscheduled surveys or patrolling are also recorded accordingly in the VPM.

Conclusion

The importance of the Industry 4.0 and its application in the Shipbuilding and Ship Repair Industry is something that needs to be nurtured and embraced by all the relevant parties involved. With the correct approach, consistent utilisation and continuous improvement, the positive effect could be achieved and felt by those in the marine industry.