by | Azmil Mohd Amin |azmil@might.org.my

The industrial revolution that began in the 18th century has undergone a series of evolution that builds upon the foundations of earlier achievements. The first revolution witnessed the emergence of mechanisation such as steam engines and mass extraction of coal. Almost a century later at the end of the 19th century, new technological advancements birthed new sources of energy—electricity, gas and oil, which resulted in the development of the combustion engine alongside the exponential demands for steel.

In the second half of 20th century, the third era of industrial revolution appeared with nuclear energy. This revolution witnessed the rise of electronics, the advent of computers and the beginnings of automation, when robots and machines began to replace human workers on those assembly lines. This new technology gave rise to the era high-level automation in production and manufacturing. These first three industrial revolutions define the contours of a fourth revolution that is unfolding right before our very eyes in this 21st century—the Industry 4.0.

The Industry 4.0 movement started in Germany, with many of that country’s leading industrial companies demonstrating strong initiatives. According to the Economist, the list includes BASF, Bosch, Daimler, Deutsche Telekom, Klöckner & Co., and Trumpf. The momentum is rapidly growing elsewhere as well, particularly in the United States, Japan, China, the Nordic countries, and the United Kingdom.

Essentially the industry 4.0 movement is envisioned to bring together humans, robots and automation in ways never before possible. This subsequently will lead to the creation of a smart factory where cyber physical machines monitors the processes in the assembly line and make decentralised decisions. The factory is now part of the Internet of Things (IoT) where it communicates and cooperates with both machines and humans in real time via the web.

However, the smart factory is just the tip of the iceberg revealing what Industry 4.0 can offer.

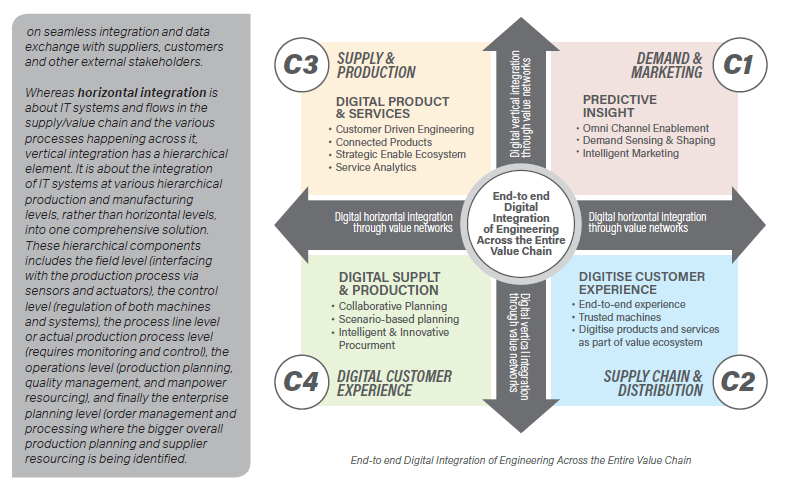

The characteristics of Industry 4.0 can be understood from the perspectives of digital horizontal and vertical integration within the Industry 4.0 ecosystem; which forms four distinctive end-to-end digitalisations in the manufacturing and production sectors.

i) Demand and Marketing

– insights of demand and marketing as a predictive consumer analytics which anticipate and understand consumer demand

ii) Supply Chain and Distribution

ii) Supply Chain and Distribution

– the linking point where supply, production and digital supply chain is being managed

iii) Supply and Production

– digital products and manufacturing services

iv) Digital Customer Experience

– includes experience through a digital interface whether its researching a product online or getting support information from a smartphone

INDUSTRY 4.0 ROLES IN DEMAND AND MARKETING

While industry 4.0 focuses on the digitalisation of manufacturing and production, embarking on the Industry 4.0 environment will also mean massive amounts of data will be collected and collated for the purpose of

understanding consumer behaviour and demand trends. This subsequently will allow the design of marketing strategies and intelligence being carried out in a holistic and intelligent approach.

PREDICTIVE INSIGHTS

Predictive consumer insights help to develop behaviour based on customer profiles and segments. Highly personalised, optimised propositions and other interventions are executed through multiple platforms of engagements based on the insight. Combining decision management, real-time scoring and omni-channel integration will provide decision makers with consistent, continuous and relevant customer engagements.

OMNI-CHANNEL ENABLEMENT

Omni-channel is an evolution of multi-channel retail but with a seamless integration of customer experience through all available shopping channels platforms such as mobile, brick-and-mortar, television, radio and prints. Opportunities are created to exploit rapid sales growth through emerging channels like mobile to promote brand awareness and loyalty.

A Deloitte study claimed that Omni- Channel customers spent 93 percent more than online customer and spent 208 percent more than in-store customers. Customer engagement is paramount and the study also observed that customers who liked a retailer on Facebook will likely spend 44 percent more time than customers who do not.

DEMAND SENSING & SHAPING

Demand sensing can be described as a specialised type of monitoring process that focuses on the identification of changes that occur in near real or real time. These incoming signals can come from big data accumulated and analysed, individually or collectively to determine the effect on the current demand plan.

The demand-sensing process uses advanced analytics to support the selection, preparation and transformation of both structured and unstructured data in support of demand and supply synchronisation. Turning data into actionable insights, which include early warning algorithms, predictive models, decision support, workflows and dashboards will allow manufacturers to make fast and accurate decisions throughout the value chain.

Demand-sensing signals that can affect expected demand trends may be used to extend the demand planning process into a demand-management decision support system. Such approach adds credibility and validity to collaborative demand and supply plans by identifying and incorporating structured and unstructured data sources such as, market segment data (e.g., Web, social media and email, collaborative customer data (e.g., demand anomalies), sales and marketing data (e.g., promotions, product lifecycle management and competitive analysis).

INTELLIGENT MARKETING

Manufacturing companies are being driven by a few impactful market trends affecting their business. The expectations of global markets are causing companies to build production processes with greater agility and adaptability to respond to highly variable market demand. Massive amounts of data being produced through social media channels have changed the way manufacturers approach consumers. For example, Artificial Intelligence (AI), an increasingly important technology assists marketers in reducing manual workloads, and enabling rapid personalisation decisions to improve targets. AI-powered predictive analytics traces and records customers’ past behaviour, allowing marketers to personalise messaging and take necessary action to meet customers’ expectations. The better AI gets, the better personalisation marketing can offer messages will become more relevant and targeted, resulting in less wastage. According to McKinsey, 35 percent of Amazon. com’s revenue is generated by its recommendation engine. This proves the power of analysing data in predicting customers needs and offering it to them.

INDUSTRY 4.0 ROLES IN DIGITAL SUPPLY CHAIN AND PRODUCTION

The digital supply chain as suggested by PWC, consists of eight key elements; integrated planning and execution, logistics visibility, Procurement 4.0, smart warehousing, efficient spare parts management, autonomous and B2C logistics, prescriptive supply chain analytics and digital supply chain enablers. Companies that efficiently consolidate all these pieces into a coherent and fully transparent whole will gain huge advantages in customer service, flexibility, efficiency, and cost reduction. Through the combination of these elements, manufacturers can execute a wholesome collaborative planning.

COLLABORATIVE PLANNING

As Industry 4.0 focuses on the end-to-end digitisation of all physical assets and integration into digital ecosystems with value chain partners, one of the attributes of digital supply chain is the ability to see and understand the activities and events of multiple players. Generating, analysing and communicating data seamlessly underpins the gains promised by Industry 4.0, which networks a wide range of new technologies to create value.

SCENARIO-BASED PLANNING

The IoT is great at using telematics, sensors and geo-positioning signals from devices to pinpoint location and condition of assets, but much of the IoT’s value is on applying the awareness to make better decisions.

In this digital age, much of the awareness can be achieved from an integration of the different points of information input. A further benefit from this awareness will be scenario-based contingency planning, where manufacturing planners will be able to anticipate future requirements of production.

As part of total logistics solutions, real-time monitoring of trucks, vehicles and goods in transit via the IoT has been around and is becoming more capable as the number and sophistication of sensors and IoT infrastructure improve. Sensors on trucks and trailers are becoming more effective—smarter and more capable of monitoring different conditions of road conditions, weather and activities of vehicles during transit.

INDUSTRY 4.0 ROLES IN DIGITAL PRODUCTS AND SERVICES

In a nutshell, digitalisation is about revolutionising products, productions and services. Usually composed solely of mechanical and electrical parts, products have become complex systems that combine hardware, sensors, data storage, microprocessors, software and connectivity in countless ways.

Industry 4.0 aims to evolve manufacturing and production practices towards the idea of smart factory. Smart factory represents a leap forward from traditional automation to a fully connected and flexible system that can optimise constant stream of data from connected operations and production systems to learn and adapt to new demands.

The idea of smart factory is to integrate data from system-wide physical, operational, and human assets to drive manufacturing, maintenance, inventory tracking, digitisation of operations through the digital twin, and other types of activities across the entire manufacturing network.

CUSTOMER DRIVEN ENGINEERING

Digital tools have changed the ways people work, shop and live. People have also become more demanding, among others with regards to fast responses and timely information. On top of that, consumers prefer a degree of personalisation. To meet these expectations, it is important to ensure efficiency and level of accuracy in production line is fully optimised. Predictive maintenance is forming a large part of an industry shift to manufacturing services. The efficiency of predictive maintenance is gained by reporting real-time engineering information—including location, running data, and status— to maintenance centres against baseline data sets for fault-modelling and failure analysis.

INTELLIGENT AND INNOVATIVE PROCUREMENT

Data analytics are probably the most important enabler for Industry 4.0 in procurement. Smart technologies and algorithms allow very large volumes of data from varied sources to be aggregated, processed, and analysed. The results can be used to predict market trends, understand suppliers, markets, and customers, as well as examine machine and product failures. They enable employers to make better, informed decisions. In some cases, procurement processes can be completed automatically.

One of the key success factors for companies that want to make the most of the innovative procurement potential is through analysis of data and using it in a smart and intelligent way. For example, suppliers could be utilising field application data analysis to improve the design and performance of their products. Predictive information about where and when to expect the next failure will offer the opportunity to optimise maintenance services and the availability of spare parts.

Modularity and flexible adaptation of smart factories to change requirements by replacing or expanding individual modules in a dynamic market is essential. In a typical case, an average company would probably take a week to study the market and change its production accordingly. On the other hand, smart factories can adapt to new market changes quicker and more seamlessly according to seasonal changes and market trends.

The ability of Cyber-Physical Systems (CPS) to make decisions and to produce locally leveraging on technologies such as 3D printing means greater decentralisation in manufacturing. Such ability to make simple autonomous decisions creates a more flexible environment for production. In cases of failure or having conflicting goals, the issue will be delegated to a higher level. However, even with such technologies implemented, the need for quality assurance remains a necessity on the entire process.

In the Industry 4.0 environment, demand will also evolve qualitatively, driven by trend towards greater mass personalisation. Customer-centric plants are likely to bridge the gap between a global, integrated supply chain already benefiting from economies of scale and a personalised approach to production and service. Leveraging Industry 4.0 technologies platform—such as digital manufacturing, 3D printing, and advanced robotics—these plants will have a range of key features. Such plants will make value chain more responsive, allowing industrial manufacturers to reach end customers more directly and create tailor made business models accordingly. Diversity in products such as aircraft engines and software are increasingly offered as services, often on a subscription basis.

CONNECTED PRODUCTS

Smart, connected products offer expanding opportunities for new functionality, greater reliability, much higher product utilisation, and capabilities that transcend traditional product boundaries. The changing nature of products is also disrupting value chains, forcing manufacturers and businesses to rethink and retool almost all internal processes.

STRATEGIC ENABLE ECOSYSTEM

Industry 4.0 focuses on the end to- end digitisation of all physical assets and integration into digital ecosystems with value chain partners encompassing a broad spectrum of technologies. A 2016 PwC report found that generating, analysing and communicating data seamlessly underpins the gains promised by Industry 4.0, which networks a wide range of new technologies to create value. Three key attributes of Industry 4.0 include digitisation and integration of vertical and horizontal value chains, digitisation of product and service offerings as well as digital business models and customer access.

SERVICE ANALYTICS

The manufacturing process in Industry 4.0 environment will require analytics based on large amounts of data for decision making actions such as to optimise production quality in the assembly line, detecting the fault or an anomaly in various machines at shop floor, addressing the issues of machine degradation and component wear etc. Both data and analytics are becoming increasingly important in the decision-making process within a smart factory.

INDUSTRY 4.0 ROLES IN DIGITAL CUSTOMER EXPERIENCE

The customer experience plays a crucial role in digital transformation in Industry 4.0 environment. Many digital transformation initiatives arise from pain points where business innovation needs and growth transformation are imperatives of the customer. These digital transformation initiatives are caused by the increasing importance of an end-to-end customer experience improvement approach, which in turn among others, is caused by changing customer expectations and customer experiences offered by the best-in-class.

Sometimes, in a digital transformation context, organisations look mainly at what has become known as the digital customer experience. Companies that transform end-to-end digital journeys can unleash fundamentally different customer experiences. The kind that are driven by a customer-centric vision as well as the digitalisation of underlying processes through smart processing technologies.

END-TO-END EXPERIENCE

It uses technology to capture the intangible value for consumers when they interact with the products, services and brands throughout a period of time. The interaction encompasses three main elements that consist of the customer’s point of contact with the brand or product and services, the customer journey and the environments in which the activities take place. By understanding the intangible values from the interaction, the end-to-end approach can be well-modelled towards a customer-focused experience.

TRUSTED MACHINE

Describes an analytic tool, like a learning capable machine, to understand consumer behaviour. By using a trusted machine, it helps in eliminating the need to fill out forms and enter tracking numbers for gathering information about the targeted customers. This creates an opening of new possibilities, delivering information faster and more efficiently than the normal practices.

DIGITISE PRODUCT AND SERVICE

Products and services are being developed from the feedback of customer experience. With the digitalisation of products or services, consumers who are interested in the products/services of a brand may, in their spare time, upload reviews and comments and respond to other reviews and comments about the product. Subsequently helping other users with technical service issues or gaining extra information about the product. These individuals can be very useful sources of product development ideas, or can be incentivised as a low-cost provider of technical service to other consumers.

CONCLUSION

Industry 4.0 is hailed as a revolutionary approach in the manufacturing industry. The concept, technology and techniques will push global manufacturers to a new level of optimisation and productivity. Additionally, customers will also enjoy a new level of personally customised products at a quicker rate, something that has never been achieved before. Not to mention, the economic rewards are simply immense.

However, there are still many challenges that need to be tackled systematically to ensure a smooth transition. This needs to be the focus of large corporations and governments alike. Pushing research and experimentation in such fields are essential.

While speculations regarding privacy, security, and employment need more study, the overall picture is assuring. The Industry 4.0 groundbreaking approach to the manufacturing industry is not only limited to supply chain and production but includes services and customer experience as well.