by | Shamsul Kamar Abu Samah, Chief Executive Officer , Aerospace Malaysia Innovation Centre (AMIC)

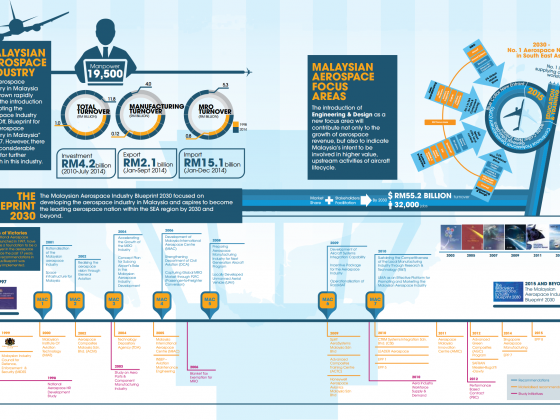

The newly developed Malaysian Aerospace Industry Blueprint 2030 is a manifestation of Malaysia in becoming a regional champion by year 2030. The blueprint outlined strategic approaches by all stakeholders involving Government agencies, industry players, research institutes and academia.

Targeting to generate more than RM35 billion industry revenue with 32,000 work forces; the plans require a robust facilitation by all stakeholders covering among others industry policies, institutional framework, investments, talent development, capturing new market and research & technology. The evolution of aerospace technology has been tremendous and the potential for future growth is enormous. The advancements of technology have taken the industry to many new levels of opportunities. In order to survive in this business as well as to sustain our competitiveness at the global arena, we have to enrich the industry through adoption of advanced technologies. One of the key success factors is to further accelerate industry-led R&T activities by modernizing our technology and processes; especially in aerospace manufacturing and MRO.

Future aircraft are expected to utilize more advanced material and technologies. This is a clear indication of changes in the future aircraft production and MRO activities. Therefore, we need to look into latest technology related to innovative manufacturing, robotic, automation, composite repair, analysis, redesign and so on. It is anticipated that more composite materials are likely to be used in the new aircraft. Even today, more than 50% of A350, 30% in A400M and 25% of A380 are composite parts. Utilisation of composite materials is among the potential areas being explored by the OEMs to reduce the weight of the aircraft and to increase efficiency that would lead to minimal fuel consumption to address the environment concern.

Malaysia is one if the industry champion for aero-structure manufacturing in the region. However, our technical capability and business expansion are limited by the longstanding technology. Therefore, if we want to remain as champion and stay ahead of our competitors, we need to invest on modernizing our processes that may include acquisition of advanced technology as well as conducting industry-led research.

Apart from aero-structure manufacturing, we are also the regional leader for aerospace MRO. To stay ahead of our competitors we have to be abreast with the latest technology. That means composite manufacturing, and composite repair will always be a big challenge as it is far different from conventional metal repair. Therefore, development and adaption of new technology are critical to sustain the business. At the same time, we need to train workers who understand and have the capability to utilize the new technology.

Aerospace technology is developing and evolving fast. We have to keep pace with the development and evolution in order to retain our competitive edge in the global market. We need to identify what are the areas that we need to improve, evaluating new technologies relevant to our vision and developing plans to elevate our technical workforce to a higher level. To implement the aerospace industry development initiatives effectively, it is necessary to leverage and further expand on the smart Public Private Partnership (PPP) approach. In this respect, AMIC is taking the lead of industry-led aerospace R&T development through consultation with its industrial lead members, namely Airbus Group, Rolls-Royce and CTRM.

Under the smart collaboration, AMIC addresses the need for industrial labs that are missing in our research structure whilst the industrial lead members share their expectations on the future of the industry. Subsequently, the team discusses the formula to escalate industry’s competitiveness through R&T and initiatives to alleviate our researchers’ capability to undertake global level projects.

In a recent development, AMIC establish partnership with M-Aerotech to develop aerospace R&T capability within Asia Aerospace City (AAC) as well as to further strengthen the nation’s human capital capacity in aerospace manufacturing industry. M-Aerotech will be focusing on the World Class Tailor Made Infrastructure providing areas for engineering services, design, stress analysis; and Professional Development to cater for the continuous development of human capital, whilst AMIC will take the lead in the Industrial R&T.

The establishment of AAC is expected to be accessible and beneficial to the local and global aerospace communities. Leveraging on AMIC technical network, we plan to bring local and international experts namely Airbus Group, University of Malaya (UM), STRAND Aerospace and University of Nottingham Malaysia Campus (UNMC) to AAC.

Moving on, we need to capture more complex work packages, explore new technologies, develop new sustainable materials, and adopt advanced processes in our manufacturing and MRO activities. The main ingredients to sustain the aerospace industry will be the focus on industry-led R&T activities. However, R&T need to be complemented with the right infrastructure and highly competent workforce.

Close collaborations and smart partnerships between the industry players, universities and research institutes are the key success factors to develop a vibrant eco-system for Malaysian aerospace industry. It is expected that under various initiatives to be promoted under the Malaysian Aerospace Blueprint 2015- 2030, the ties between the respective parties will become stronger so that we could become a world class aerospace research community.